About "RASHIX"

Radiation Shielding Ceramics

RASHIX

"RASHIX (Lasix)" is a ceramic that can efficiently shield radiation.

Ceramics are known for having fireproof and heat insulation properties, but "RASHIX" has a density of 4.9 g/㎤*, that overturns common standards; with its high density, it shields radiation more efficiently.

Conventionally, lead and lead-containing materials have been used for radiation shielding. However, lead is difficult to process and to install, the substances are harmful to the human body as well as the global environment. It brought great concern, so substitute materials were sought in the market.

At Mitsuishi Taikarenga, we utilize iron oxide which is a by-product of other industries as a material for "RASHIX". By combining our refractory brick manufacturing technology cultivated over 120 years since our founding, we have contributed to environmental purification by using by-products as raw materials.

A ceramic, "RASHIX", is characterized by the very high radiation shielding capability and for its easy manufacturing. It is a safe, raw material without any burden on the human body or the environment.

*Concrete Specific Gravity=Approx. 2.3g/㎤

Naming of RASHIX

Radiation +Shield +Ceramics

Radiation: is energy transmitted in waves or a stream of particles.

Shield: is a cover that protects whatever is behind or beneath it.

Ceramic: is made out of clay and baked in a kiln until it's very hard.

"RASHIX" is the only ceramic commercialized for radiation shielding.

RASHIX Production Method

-

STEP01

Material Iron Oxide

We use "iron oxide" which is a by-product of other industries.

-

STEP02

Molding

Material is put in the formwork and molded with a press machine.

-

STEP03

Sintering

Volume Reduction High Density of 4.9g/㎤

Technique used to consolidate high density powder at high temperature. When powder is pressed and heated at a temperature below the melting point, bonding occurs between the powder particles and becomes solid. It’s then applied to the manufacturing of various ceramic products. -

STEP04

Inspection

Check all products to ensure they meet the standards.

-

STEP05

Completion

Deliver to each customer.

After gathering 120 years of experience using our original refractory brick manufacturing technology,

we have added a high-value, high function product, “RASHIX”.

Patents

Currently, our product is patented in Japan, the United States, South Korea, and China. Germany is patent pending.

The Characteristics of RASHIX

Protect Human Life and Our Earth with "RASHIX"

"RASHIX" has characteristics that protect human life and the life of the earth. The characteristics can be roughly classified into the following six categories.

Specific Gravity Properties

High Specific Gravity that Overturns the Norm

The greatest material property affecting the radiation shielding ability is the specific gravity, but "RASHIX" has a high density of 4.9 g/㎤.

It has a high specific gravity characteristic more than double that of concrete (specific gravity = about 2.3g/㎤ *confirmation on the other side).

This high specific gravity efficiently shields radiation.

Excellent Shielding Performance

The shielding effect from radiation in RASHIX has been confirmed to have high performance as a result of various verification tests conducted by independent administrative agencies, such as Tokyo Metropolitan Industrial Technology Research Institute, Okayama University of Science and Osaka Prefecture University in various fields.

RASHIX has a density of 4.9g/㎤, and it can efficiently shield radiation.

Also, if RASHIX has the same transmittance as concrete, it can be about half the thickness of standard concrete. By reducing the thickness of the structure in half, you can effectively use it on land and buildings.

In the temporary storage of decontamination waste in Fukushima prefecture, we shielded gamma rays from waste in the RASHIX shielding box and measured the decrease in radiation doses.

The result was a shielding rate of 98.47% with a shielding thickness of 17cm, which officially confirmed the shielding performance of RASHIX.

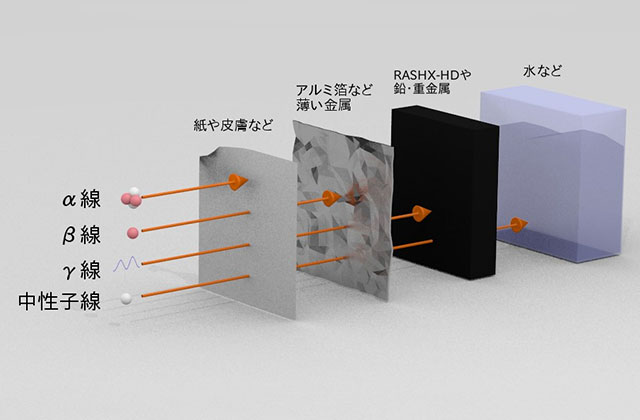

Basic Knowledge of Radiation

There are various radiation types such as alpha rays, beta rays, gamma rays, X rays, neutron rays, and the like.

Among these, alpha and beta rays have low permeability. For example, alpha rays can be shielded by one sheet of paper, whereas beta rays can be shielded with thin aluminum foil.

Gamma and X rays are high electromagnetic waves with high energy transmission, and it is impossible to completely shield them with ordinary substances.

Lead and other materials are well known as shields of gamma and X rays.

RASHIX can efficiently shield from both gamma and X rays.

Fast neutron rays generated by nuclear reactions can be decelerated by water and absorbed by boron or the like, however the principle is different from shielding of gamma and X rays.

Safety

Radiation Shielding Material that Replaces Lead

Generally, radiation shielding materials are made by blending lead and tungsten.

However, lead is toxic, and strict precautions are required for installing it in various locations and also managing it. Laws and regulations have also been enacted for manufacturing locations and methods, and various considerations are required when installing and usage is also limited.

"RASHIX" is a ceramic that sintered "iron oxide" which is a by-product of other industries.

It is safe to the human body and easy to manage the usage and disposal of.

In addition, by effectively utilizing by-products, we’re also contributing to environmental cleanup.

Even from the perspective of safety and cost effectiveness, we’re confident there are no radiation shielding products that are better than "RASHIX".

Mechanical Characteristics

Can be shaped freely

It is no mistake to think that the shielding effect of radiation is simply proportional to the density of shields. The heavier (thicker) of the material, the shielding effect is also higher.

However, there are various restrictions and conditions on the size and construction spaces in order to install the shields.

If the wall thickness needs to increase, you're not able to secure indoor space, or the weight may increase, which then may require foundations or ground reinforcement.

At Mitsuishi Taikarenga, we focused on the size of the specific gravity = heavier weight per volume, and not the thickness. The higher the specific gravity, the higher the ability to shield the radiation per unit volume.

"RASHIX" overturns the norm by our own sintering technology that realizes the specific gravity.

Compared to concrete, we made it possible to make it about half the thickness with the same shielding ability.

Because it is safe for human bodies and ceramics are easy to manufacture, it can also be used as additional shielding for wall material for private homes, existing buildings, medical X-ray treatment equipment and etc.

-

■ Can be shaped freely

It can be manufactured according to the application and design.

-

■ High strength

Pressure resistance is very high at 200MPa and it is possible to build a robust structure.

-

■ Heat-resistant

"RASHIX" is fired as high as 1300°C and can also be used in hot places.

-

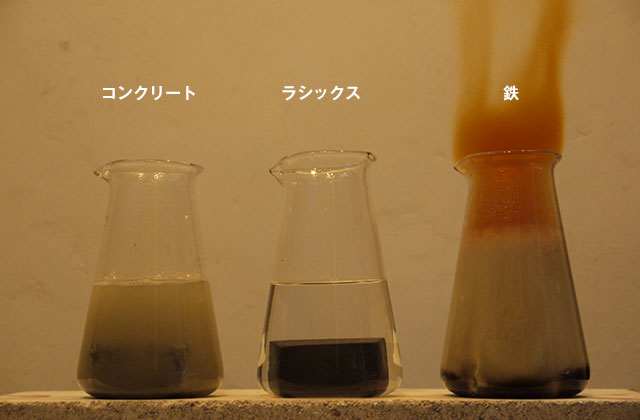

■ Chemical resistant

It is a stable material against acid, alkalis, and salt. After conducting an acid resistance test with diluted sulfuric acid, concrete and iron dissolved, but showed no changes to "RASHIX".

-

■ Abrasion resistant

"RASHIX" is a ceramic that is fired for a long-time under high-temperature so it does not change with time.

Even if it is exposed to weather, ultraviolet rays and salt, it will stabilize over a long period without rust or corrosion, unlike metal.

-

■ Mass production is possible

The raw material is iron oxide that can be obtained in large quantities.

Lead and tungsten used for general radiation shielding materials has been decreasing in mass quantity due to the dwindling of resources.

We must work more seriously on areas of energy conservation, recycling, and effective utilization of resources, while manufacturing radiation shielding material on this finite earth.

The raw material of "RASHIX" is iron oxide which is a by-product of other industries.

By combining refractory brick manufacturing technology cultivated over 120 years since our founding, we contribute to environmental purification using by-products as raw materials. It is not too much to say that "RASHIX" can be mass-produced with accessible resources and is the future of radiation shielding materials that protects the future of the earth.

RASHIX Usage

Applications of "RASHIX" Spreading in Response to Needs

"RASHIX" can demonstrate its strengths in a wide range of areas from industrial to living materials.

We will continue to strive to be useful in various fields.

-

● Medical Field

Radiation shielding materials for X-ray safeguards in medical facilities, linear accelerator/heavy particle therapy equipment, etc.

· For wall materials of radiology laboratory and radiotherapy rooms

· As an easy shielding material in operating and hospital rooms where radiation shielding is difficult to install -

● Disaster area · Restoration work

Safety assurance of workers surrounding radiation and decontamination storage containers of radioactive waste.

· Protection of workers from the dangers of radioactive environments and contaminated substances, to simple shielding of waste -

● Nuclear power related equipment

· Worker protection in a radioactive environment

· Install inside a nuclear power plant or a shelter for workers as an emergency countermeasure place -

● Government and public facilities

· For usage in a wide area evacuation site, and shielding material for new shelters

-

● Work and resident related

· Lamination of existing buildings, walls, doors and ceilings

· Construction materials, such as wall and floor materials when buildings and living spaces are newly built

Inquiries about RASHIX

By phone or fax

TEL.0869-62-0541 FAX.0869-62-0565